CAD, Project Management, System integration, 3DP

Personal project | 2025

Topic: Design and manufacturing of custom 3D-printed watchmaking tools

These tools were born from my personal need to improve my watchmaking workspace while optimizing both cost and quality of accessories. I chose to design and manufacture the various supports and devices myself using 3D printing and my mechanical design experience.

After purchasing a set of 10 watchmaker screwdrivers, I was not satisfied with the available commercial stands, often expensive and impractical. I designed on Creo a rotating stand, 3D printed, using a 61813zz bearing from my stock. No drilling, screwing, or cutting: everything is assembled by press-fit. The bearing provides the necessary stability, with optional anti-slip pads underneath. The stand includes slots for the 10 screwdrivers, spare blades, tweezers, pliers, and long tools (hand removers). The sizes are engraved in relief and hand-painted with paint markers. Internal recesses were added to prevent cooling defects during 3D printing. The base is chamfered to minimize the "elephant foot" effect from the print bed.

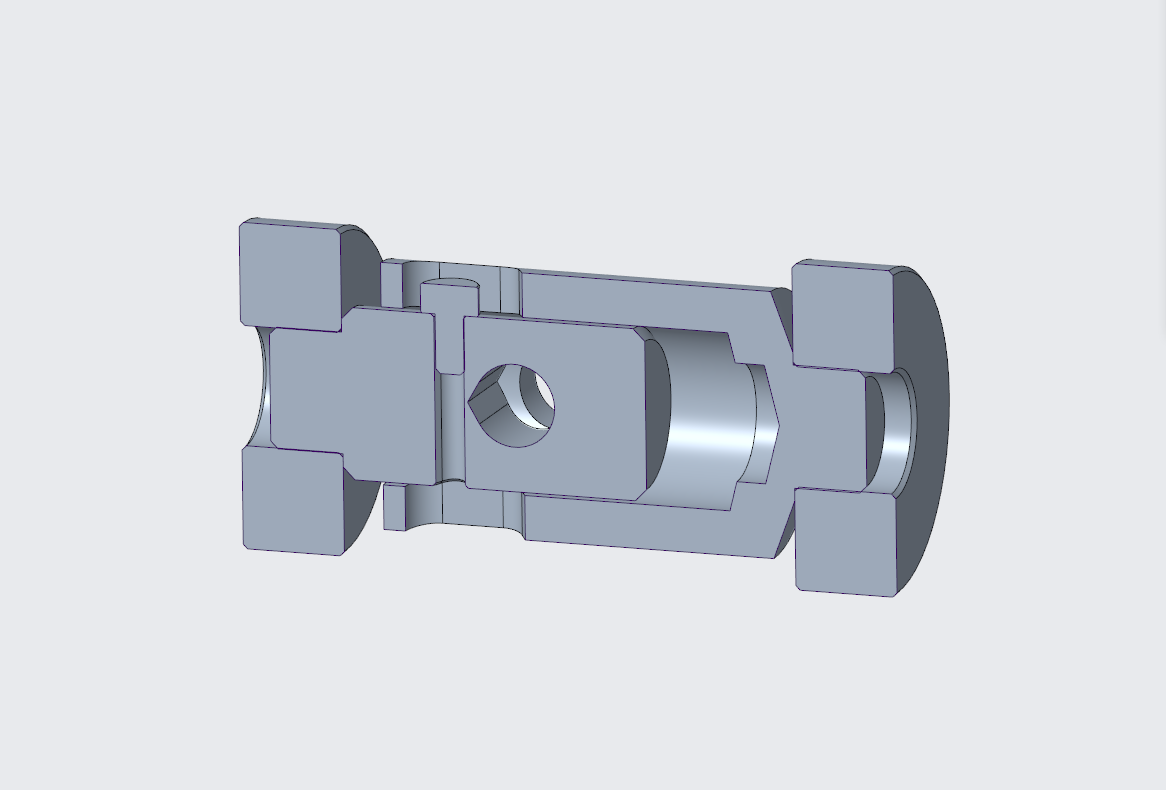

Inspired by a very cheap sharpener I previously owned, I redesigned the concept to greatly improve its precision and mechanical stability. Designed in Creo and fully 3D printed, it uses two 608zz bearings, a spring, and two M2 screws. The bearings are press-fit into the housing, and the spring automatically clamps the screwdriver between the two jaws. The M2 screws are directly threaded into the printed plastic: the holes are slightly undersized to create a solid thread in the material. Additionally, the screw holes are shaped as teardrops to reduce overhang issues during 3D printing and improve structural integrity. For sharpening, I use sandpaper sheets glued to the back of a glass mirror, providing a perfectly flat surface (which also serves as my paint palette).

Based on a model found online, I redesigned stacking compartment trays that can lock together. A rail and locking tab system keeps trays stacked vertically. The trays snap together with a very satisfying "click" using the flexible properties of 3D-printed plastic. I also designed optional TPU (flexible plastic) inserts for the compartments to improve part adhesion.

This project allowed me to apply my skills in mechanical design, 3D printing, and functional optimization. Every part was specifically designed for daily watchmaking use, with simple, tool-free, reliable, and easily reproducible assemblies. I particularly enjoyed fine-tuning printing tolerances and integrating standard mechanical components into custom designs.

- Experimenting with other printing materials for contact surfaces

- Designing additional compartments for more watchmaking tools

- Producing multiple sets to organize different sections of my workbench

Mechanical Design (Creo), 3D Printing, Dimensional Tuning, Integration of Standard Mechanical Components, Rapid Prototyping, 3D Printing Optimization